The EBM NM series is an AC servo tightening shaft utilizing next-generation digital technology. As one of the most cost-effective tightening shafts available, the EBM NM series offers models with tightening torque ranging from 1 to 8000Nm. Developed by Weiwu Industrial, the EBM NM series integrates a dedicated servo drive control unit with EBM tightening shaft units to form the EBM tightening system. The shaft controller contains built-in tightening parameters, facilitating implementation of various tightening solutions. Standard models achieve ±2% precision, and the series operates on standard single/three-phase AC power while meeting high-precision, robust, and safety requirements. The EBM series supports multiple bus/RS485/RS232 interfaces, with standard models featuring 8-in-8-out I/O ports and compatibility with the MODBUS protocol. When paired with EBM upper-level tightening controllers, it enables quick and efficient configuration of tightening systems for multi-axis process control.

Item No :

EBM NM Series Tightening ShaftOrder(MOQ) :

1PCPayment :

T/TProduct Origin :

ChinaColor :

BlackShipping Port :

XiamenLead Time :

15daysThe EBM NM series is an AC servo tightening shaft utilizing next-generation digital technology. As one of the most cost-effective tightening shafts available, the EBM NM series offers models with tightening torque ranging from 1 to 8000Nm. Developed by Weiwu Industrial, the EBM NM series integrates a dedicated servo drive control unit with EBM tightening shaft units to form the EBM tightening system. The shaft controller contains built-in tightening parameters, facilitating implementation of various tightening solutions. Standard models achieve ±2% precision, and the series operates on standard single/three-phase AC power while meeting high-precision, robust, and safety requirements. The EBM series supports multiple bus/RS485/RS232 interfaces, with standard models featuring 8-in-8-out I/O ports and compatibility with the MODBUS protocol. When paired with EBM upper-level tightening controllers, it enables quick and efficient configuration of tightening systems for multi-axis process control.

Optional motors are available from Japan or Europe and America.

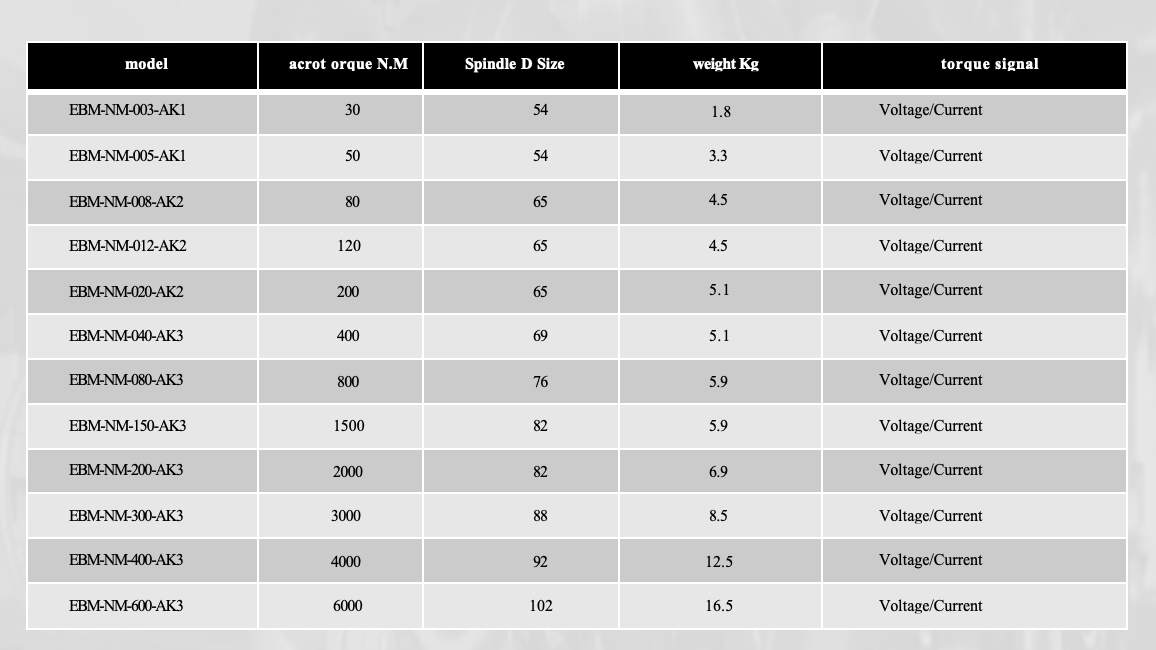

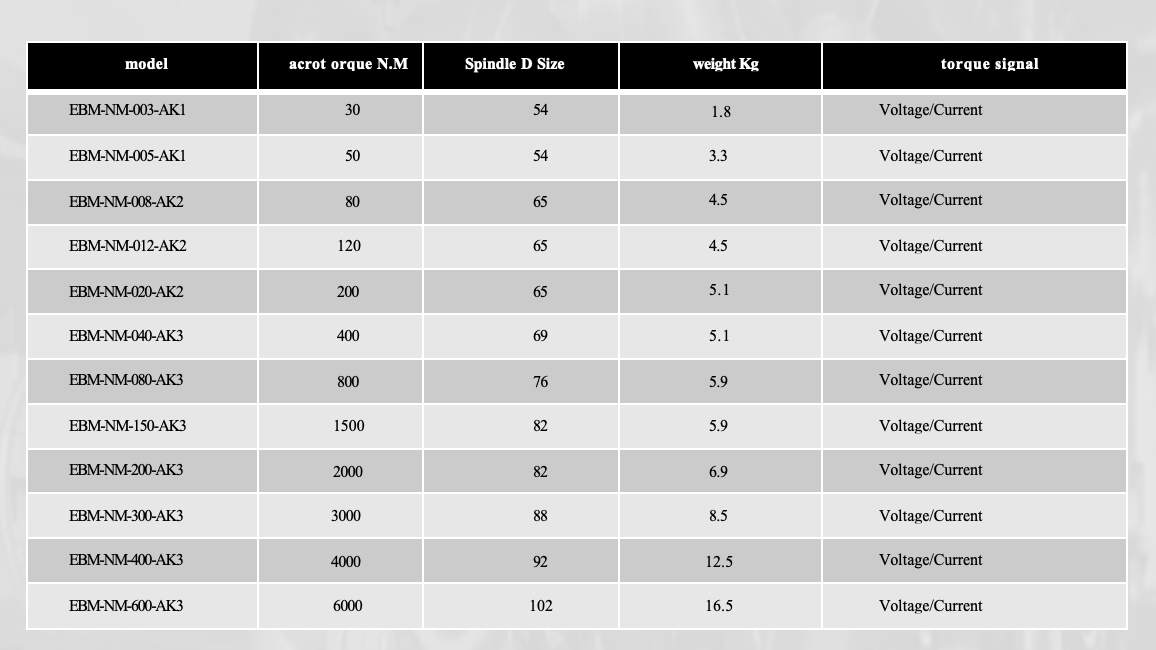

Supports 1NM-8000NM, with multiple models available

Supports multiple communication protocols including MODBUS, PROFIBUS, and CANopen (optional)

Save, read, print, or generate reports

Tags :