INTELFORCE Industrial pneumatic tools offers a wide range of pneumatic assembly tools to help you achieve maximum productivity on your assembly line. After decades of development, we offer tools that deliver maximum productivity, including ergonomically designed screwdrivers, pulse tools, nutrunners and impact wrenches. The high productivity of the tools means less air consumption, and the reduction in energy consumption and CO2 emissions leads to significant energy savings. Vibration and noise levels are reduced to an ultra-low level, and the power-to-weight ratio remains high. All this adds up to excellent operator comfort and outstanding individual productivity.

material quality

The material determines the type of screw or tightening tool and the size of the tightening force. The most commonly used materials are "iron, aluminum, plastic and different types of wood".

friction force

To ensure the quality of assembly work on the production line and achieve consistency in control, the influence of friction generated at the mating surfaces must be taken into account, such as that caused by screw bearing surfaces, threads, washers, etc. During the process of tightening a screw, typically 90% of the torque is lost due to friction, leaving only 10% of the torque to actually tighten the screw and generate the axial force.

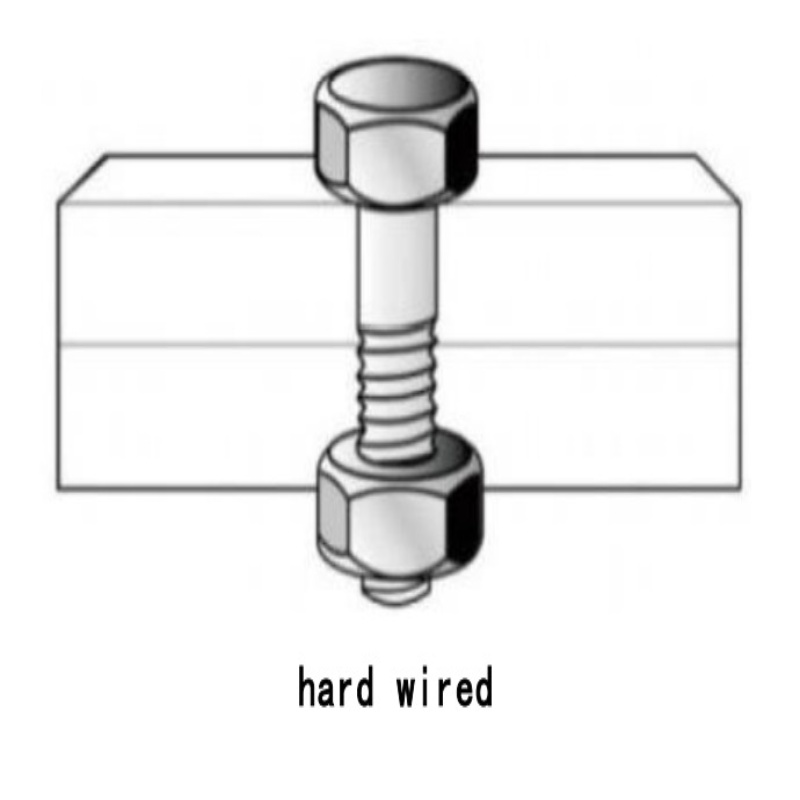

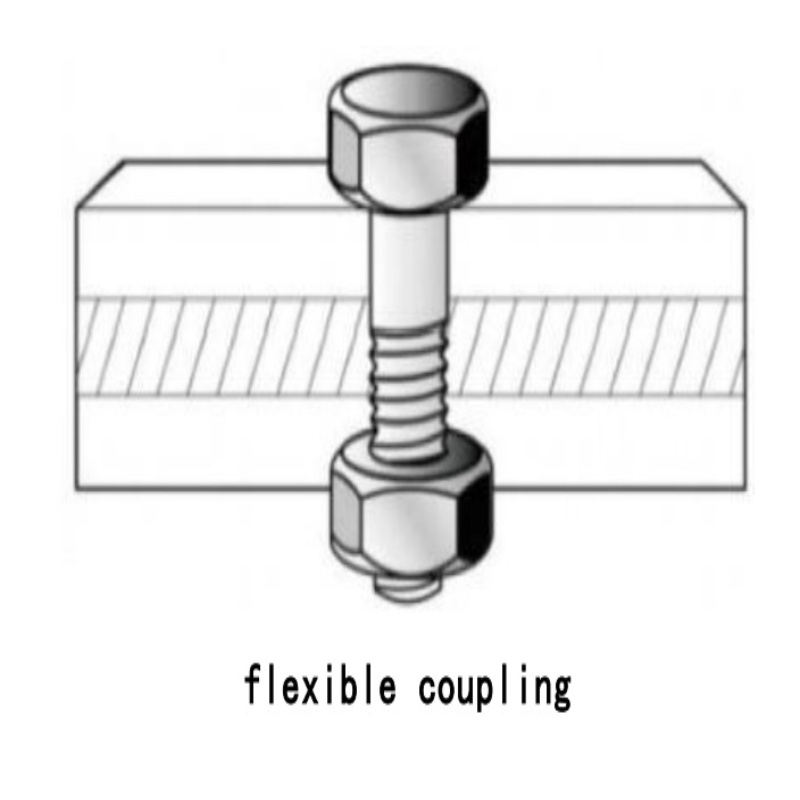

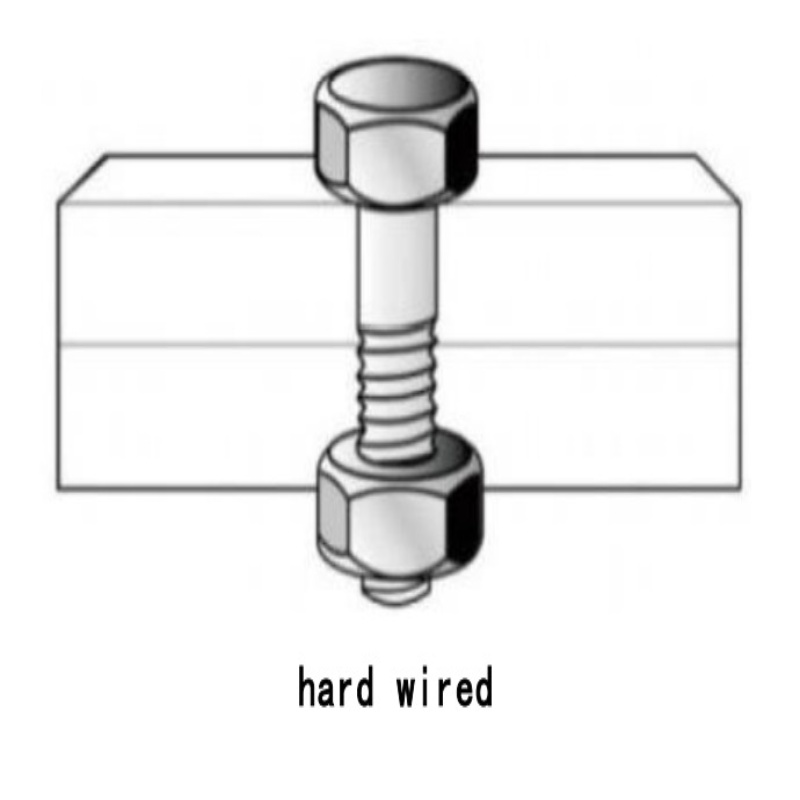

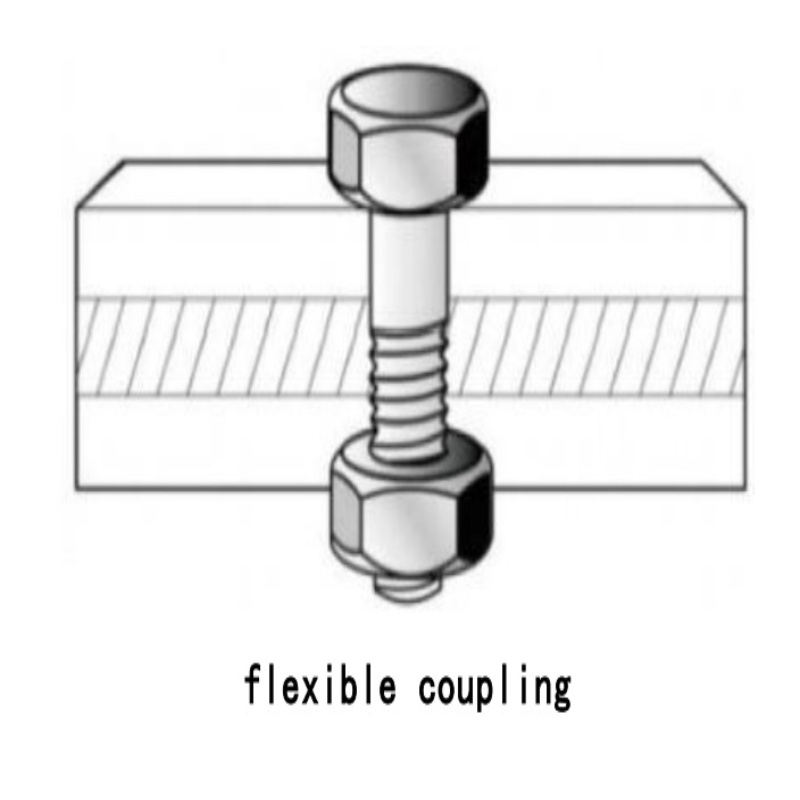

Hard connection vs. Soft connection

Hard connection: The angle from the moment the bolt is pre-tightened to the mating surface of the workpiece until the bolt reaches the final tightening torque is less than or equal to 30 degrees.

Soft connection: The angle from when the bolt is initially tightened against the mating surface of the workpiece to when it reaches the final tightening torque is greater than 720 degrees.

Therefore, when selecting tools, it is essential to consider the actual work position. The torque values for the same tool in soft and hard connections can be different. Even for the same work position and bolt, the addition of a washer can cause a "mean deviation" in the torque value.