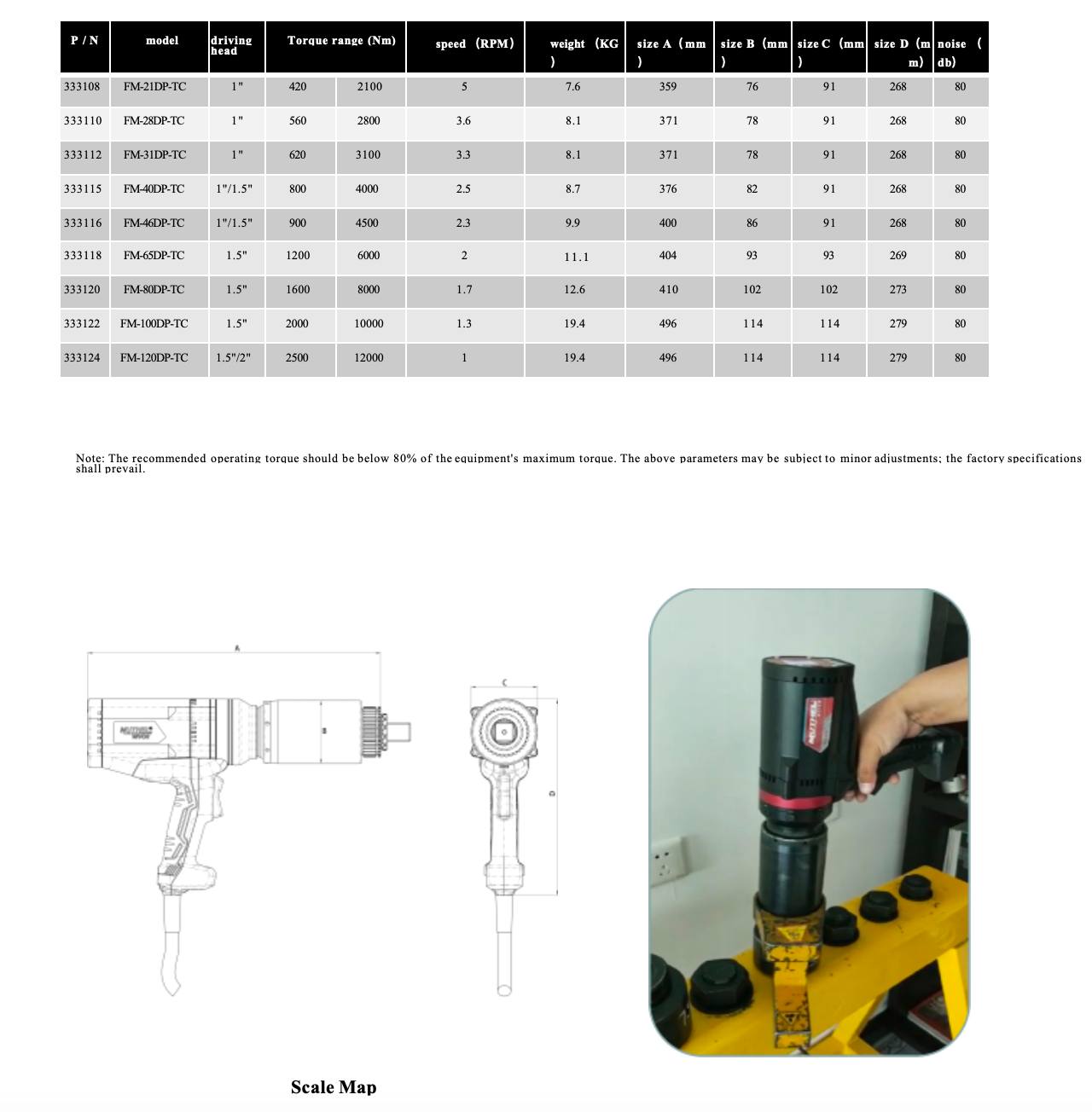

The FM-DP-TC series represents the latest generation of brushless CNC torque wrenches. Featuring integrated torque sensors and closed-loop control, these devices utilize cutting-edge brushless motors that eliminate carbon brushes, ensuring maintenance-free operation and enhanced durability. Capable of starting immediately upon standard power supply, they meet stringent requirements for high precision, robust performance, and safety. The FM series incorporates a high-power-output planetary gear reduction system.

The FM series achieves precise torque control via a color control panel, delivering smooth and continuous torque output through a high-performance digital control module. With ±4% accuracy and angle adjustment capability, it ensures reliable performance.

Item No :

FM-DP-TC Intelligent Brushless NC Electric Torque WrenchOrder(MOQ) :

1PCPayment :

T/TProduct Origin :

ChinaColor :

BlackShipping Port :

XiamenLead Time :

15daysThe FM-DP-TC series represents the latest generation of brushless CNC torque wrenches. Featuring integrated torque sensors and closed-loop control, these devices utilize cutting-edge brushless motors that eliminate carbon brushes, ensuring maintenance-free operation and enhanced durability. Capable of starting immediately upon standard power supply, they meet stringent requirements for high precision, robust performance, and safety. The FM series incorporates a high-power-output planetary gear reduction system.

The FM series achieves precise torque control via a color control panel, delivering smooth and continuous torque output through a high-performance digital control module. With ±4% accuracy and angle adjustment capability, it ensures reliable performance.

automatic decoupling rotation

10 preset values for quick adjustment

The use of brushless motors eliminates commutator wear, obviates the need for carbon brush replacement, and simplifies maintenance.

The bolt torque reference table format facilitates the identification of appropriate torque values.

User (operator, administrator) level management

Gain adjustment function for convenient and rapid torque setting

Supports gear adjustment mode with convenient adjustment, suitable for construction environments

Exceptionally high power-to-weight ratio, wider torque range, lighter and more compact.

The target torque is set and displayed digitally via the CNC panel, with torque adjustment capability for increment or decrement by 1Nm.

Supports generator power supply in field environments, more robust

This device can store more than 50,000 pieces of information*P

Overheating temperature monitoring function of wrench

voltage monitoring and compensation

accuracy ±4%

Tighten results follow monitoring (failed, succeeded, incomplete)

Optional Bluetooth or WIFI module with torque gateway system, supporting IoT connectivity to host computer and MES management system*-W/B

Supports data backup and upload, with angle function-P

Supports third-party smart torque calibration, uses software to adjust gain and hardware compensation, and extends tool service life

The torque output is stable and less affected by voltage fluctuations and long-distance cables, making it suitable for construction site applications.

Optional mobile module *NB

Tags :